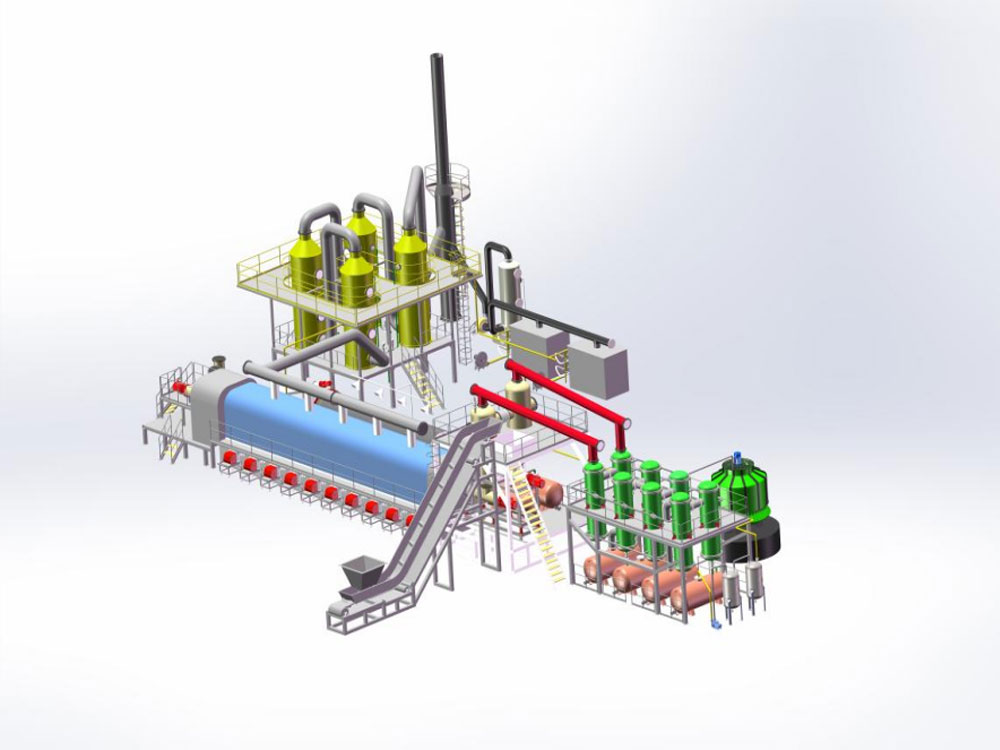

Capacity:30-100 tons per day

Application:Rubber Block,Rubber Powder, Waste Plastic,Oil Sludge, Hazardous Waste

Advantages:Automatic Continuous

End product:Pyrolysis oil,Carbon black,Combustible Gas

Raw Material:All kinds of rubber block,rubber powder, waste plastic,oil sludge, hazardous waste

The disposal of Project background:waste tires and plastics is a global challenge, as a large amount of discarded plastic and rubber products are indiscriminately discarded or incinerated, posing a great threat to the environment and health.

Fortunately, pyrolysis technology can solve this problem. By using a waste tire pyrolysis machine, we can convert waste tires or plastics into valuable resources such as fuel, carbon black, and steel wire. This environmentally friendly approach not only reduces the environmental burden of solid waste, but also contributes to sustainable energy production.

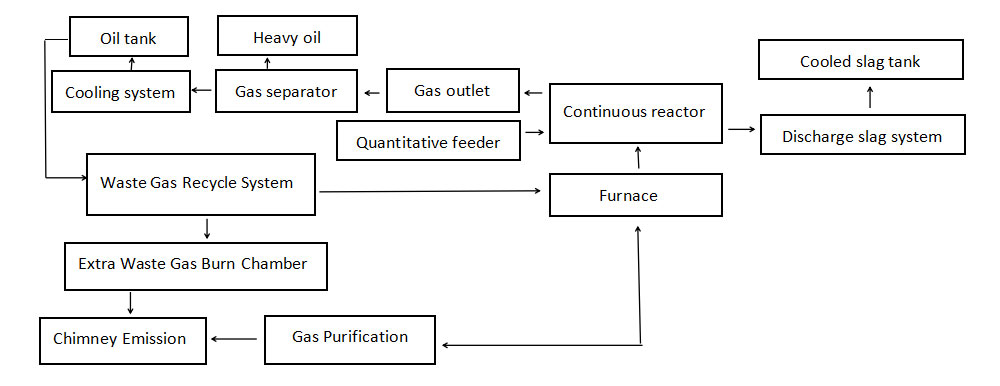

1.Feeding, with the fully closed automatic feeding machine will be a steady flow of raw materials into the reactor

2.The raw materials gradually melt in the pyrolysis reactor with the continuous rise of temperature, and the oil and gas pyrolysis

3.Oil and gas enter the condensing system and continue to produce oil

4.At the same time, the carbon black is transferred to the carbon black cooling furnace through the slag extractor

5.Process is continuous production, sustainable production of 25 days.

| Serial | Item | Technical reference |

| 1 | Suitable raw material | Less than 5cm waste tyre block or powder,waste plastic |

| 2 | Working form | Full continuous |

| 3 | Structural style | Horizontal rotation |

| 4 | Feeding and discharging | Simultaneously automatic feeding and discharging via high temperature |

| 6 | Working pressure | Negative micro-pressure |

| 7 | Rotational speed | 1RPM/2mins |

| 8 | Power | 110KW |

| 9 | Cooling method | Water recycled cooling |

| 10 | Kind of drive | Gearing drive |

| 11 | Heating method | Hot wind |

| 12 | Noise | Less than 85db |

| 13 | Installation area | 500m² |

1.Automatic continuous production, advanced technology, good oil quality

2.Automatic high temperature closed slag, environmental protection and clean no dust

3.The unique anti-sticking wall device enables continuous production of special raw materials

4.The processing capacity is large, and the daily processing capacity can reach 30-100 tons. No fuel is required and the non-condensable gas produced by pyrolysis is recovered to support combustion.

5.Environmental protection and pollution-free, (can meet the general hazardous waste treatment standards) national patent desulfurization dust removal, remove acid gas and dust in the dust.

6.Easy to operate, save labor

1. Pyrolysis oil

Directly used for industrial or boiler heating (such as cement plants, steel plants, glass plants, etc.) as a substitute for fuel oil.

Refined again into non-standard diesel that can be used for trucks, tractors, etc.

(Note: The oil directly produced by the pyrolysis plant is heavy fuel oil, which can be used as industrial fuel. If you need to obtain non-standard diesel, you need to purchase an additional set of waste oil distillation equipment.)

2.Carbon black

Sell out directly as coal (heating value is higher than coal,but cost is lower than coal,so it is easy to sell out),mainly use to burn

Can deep processing into high grade for wider usage,but need to invest grinding machine.

3.Combustible gas

Combustible gases are transported to the heating system as fuel supply.

Saves fuel consumption

Capacity:15-30 tons per day

Application:Waste Aluminum Plastic

End product:Pyrolysis Oil

Capacity:15-30 tons per day

Application:Circuit Board

End product:Pyrolysis Oil

Capacity:15-30 tons per day

Application:waste rubber block (1-2cm), rubber powder, waste plastic, etc

Advantages:Low fuel consumption, low noise, high automation, no secondary pollution

End product:Fuel oil,carbon black

Application:Waste Tyre

End product:Pyrolysis oil