Capacity:10 tons

Application:Waste Engine Oil,Pyrolysis Oil, Crude Oil, Heavy Oil,Ship Oil,Lubricating Oil

End product:Pyrolysis Oil

Raw materials: waste engine oil,pyrolysis oil, crude oil, heavy oil,ship oil,lubricating oil

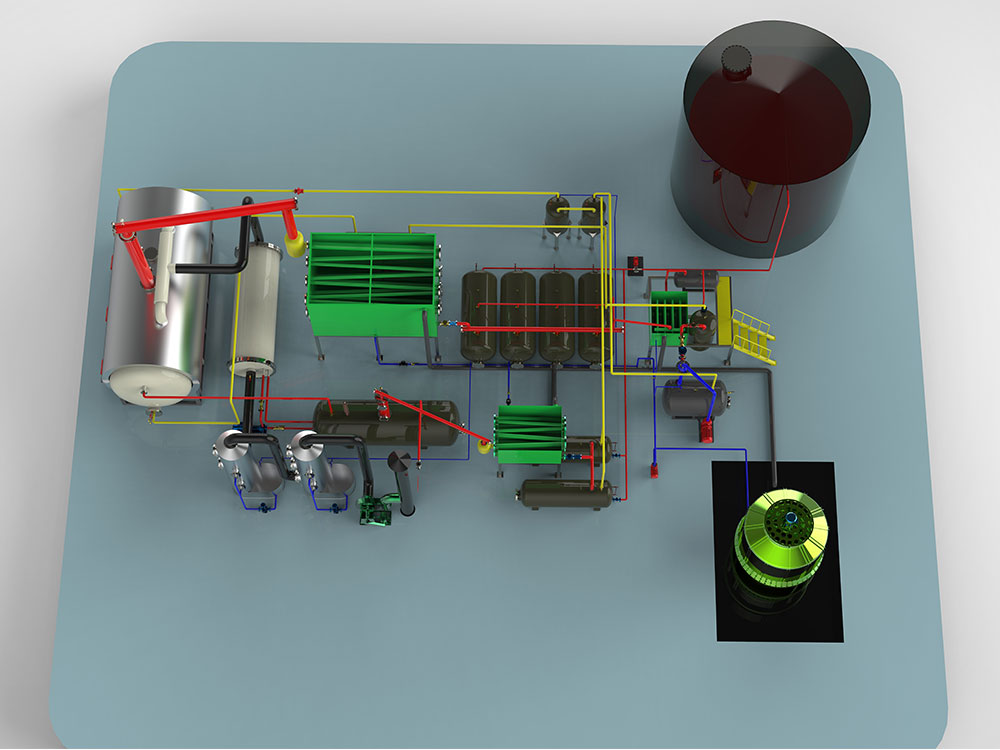

Project of Distillation Plant

Waste oil distillation plant is used to turn pyrolysis oil, crude oil, heavy oil, used engine oil into diesel.

Diesel is an alternative for oil resource. It is an eco-friendly way to dispose of waste oil.

Waste oil distillation not only helps to relieve energy crisis, but also prevents the environment from contamination. What’s more, you will get great profits from the project.

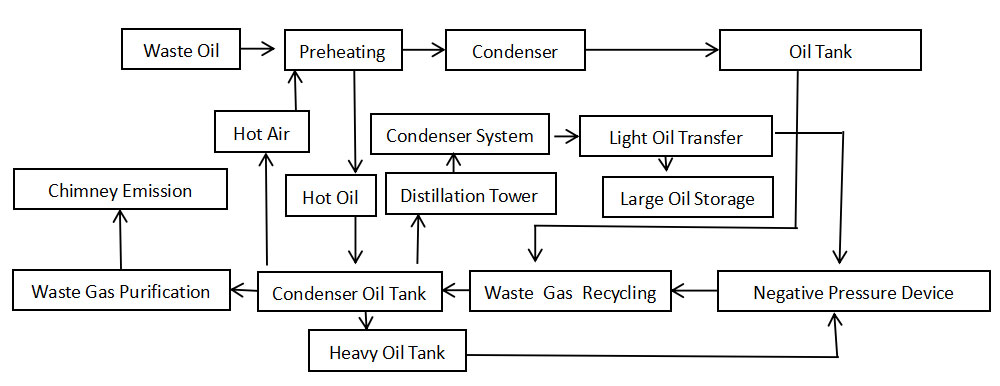

1.Pump waste oil etc. into the preheating oil tank (the heating source of the preheating tank comes from the combustion chamber of the distillation tank), and heated to a certain temperature,then will go into distillation reactor (About one hour)

2.The waste oil after preheating is continued to be heated in the distillation reactor, after heating to a certain temperature, the oil and gas is distilled out, and oil gas is cooled into oil after the distillation tower and stored in the light oil tank. (About 20 hours)

Small amount of non-liquefied gas is introduced into the combustion chamber through the recycling system to.

3.heat the distillation reactor to save fuel.

4.The combustion waste gas produced by heating is treated by the purification system and release via the chimney

5.The oil in the distillation reactor is refined to the state of heavy oil and then left the distillation reactor (about one hour)

6.Pump the oil from the preheated tank into the distillation reactor for the next production cycle

7.The whole production process is slightly negative pressure, safer and better oil quality.

|

Distillation reactor |

|

Preheating system |

|

Distillation tower |

|

Condenser system |

|

Oil tank |

|

Negative pressure system |

| Cover area | 40m*30m |

| Total weight | About 50T |

| Average power | 32KW |

| Supply voltage | 380V |

| Average loading capacity | 10T |

| Power consumption | 250KW |

| Fuel consumption | About 380KG |

1.Large capacity, automatic continuous production, advanced technology, daily processing capacity of 10-500 tons;

2.Preheating system to speed up production and improve efficiency. Reasonable production arrangement, non-sticking wall, easy to clean

3. Safety: automatic submerged arc welding technology, ultrasonic non-destructive testing, manual and automatic safety devices, indirect heating, high safety performance;

4.Unique horizontal design, high conversion rate, good benefit, considerable profit;

5.The production process is slightly negative pressure, high safety and good oil quality

6.Unique insulation shell design: excellent insulation effect, good energy saving effect

7. Condenser cooling thoroughly, high oil yield, good oil quality, long service life, easy to clean

8. Unique desulfurization dust removal system: can effectively remove acid gas and dust, to meet the relevant national standards

9.Control system has a high degree of automation, and the operation of the entire production line can be fully displayed on the control table, which is more intuitive and comprehensive.

Application:Waste Tyre

End product:Pyrolysis oil

Capacity:15-30 tons per day

Application:waste rubber block (1-2cm), rubber powder, waste plastic, etc

Advantages:Low fuel consumption, low noise, high automation, no secondary pollution

End product:Fuel oil,carbon black

Capacity:15-30 tons per day

Application:Circuit Board

End product:Pyrolysis Oil

Capacity:15-30 tons per day

Application:Waste Aluminum Plastic

End product:Pyrolysis Oil