Application:Waste Tyre

End product:Pyrolysis oil

Raw Material: All kinds of waste tires and rubber products

Eliminate black garbage, all kinds of waste tires around you can be treated environmentally through this equipment, turning waste into treasure, such as car tires, truck tires, bicycle tires, motorcycle tires, line tires, engineering tires and so on.

Compared with the traditional tire disposal method of incineration and landfill, Pyrolysis waste tires has the characteristics of large processing capacity, high economic benefits and low environmental pollution. It can not only recover high value-added products, but also has high economic and environmental benefits.

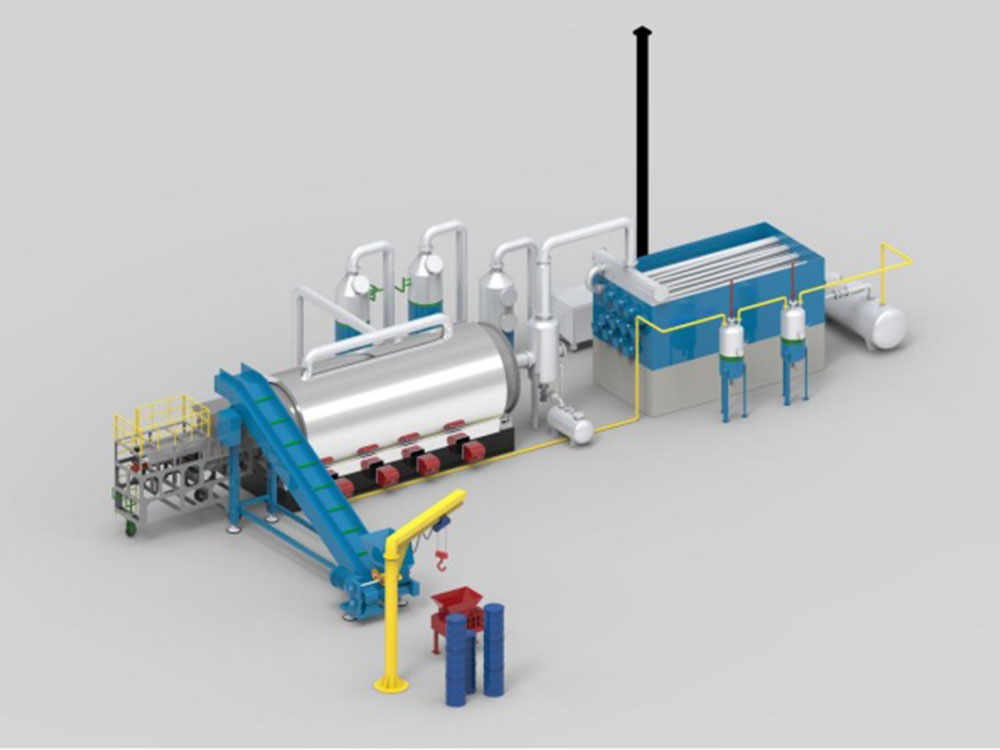

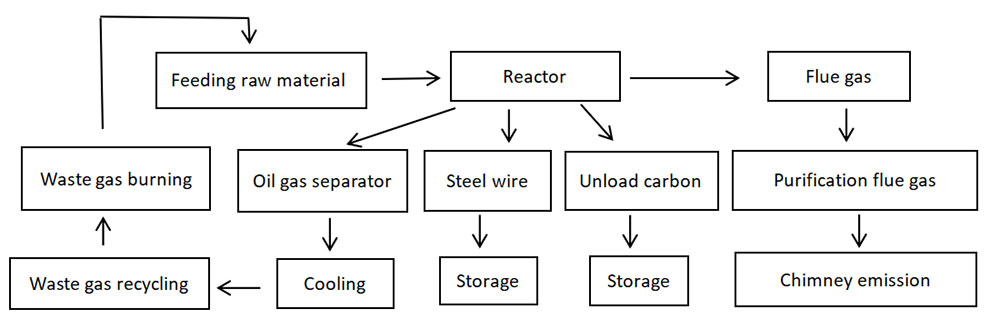

1.Loading (about 2 hours), use a fully enclosed automatic feeding machine to feed the raw materials into the reactor ( or feed by manual,waste time and labour)

2.Preheating (3-4 hours), the raw materials gradually melt with the continuous increase of temperature, and oil gas are pyrolysis

3.Peak oil production period (around 6-7 hours). After passing through the dewaxing device, the oil and gas enter the cooling system to cool into liquid fuel. A small amount of non condensable combustible gas is sent to the combustion chamber of the pyrolysis furnace for heating after passing through a water sealed tank,to save fuel.

4.After the oil extraction process is completed, stop heating, and after cooling for a certain period of time, the carbon black is sealed and discharged through the slag extractor to be transported and stored,then take steel wire come out.

5.Open the closed feeding system (optional) to feed and enter the next production cycle.

|

Special insulation layer with good insulation effect

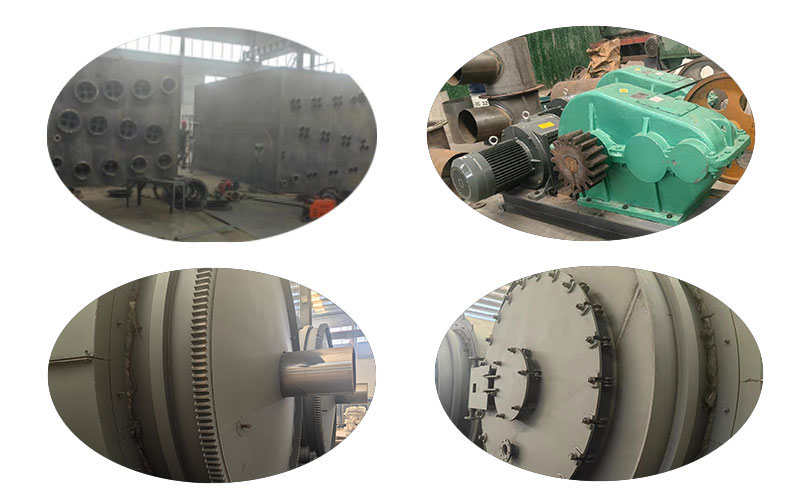

The main reactor is made of standard boiler steel |

|

Compact feeding, fast feeding speed, capable of high-temperature feeding (optional) |

|

The uniquely designed box type condenser enjoy good cooling effect and easy to clean. |

|

Non condensable combustible gas recycle system safely recycling waste gas into the combustion chamber to burn to save fuel |

|

Purify the exhaust gas generated by combustion and discharge it after meeting the emission standards. |

| Cover area | 30m*20m |

| Total weight | About 40T |

| Average power | 25KW |

| Supply voltage | 380V |

| Average loading capacity | 15T |

| Power consumption | 250KW |

| Fuel consumption | About 480KG |

1.Automatic pressure relief device, which automatically releases pressure when the pressure exceeds the limit value due to operational negligence

2.The non condensable gas purification and recycle system removes acidic gases and small amounts of oil substances through purification tanks. The purified non condensable gas is poked into the combustion chamber of the reactor for heating after passing through a water sealed tank. The water sealed tank can separate oil and gas, prevent the back-flow of combustible gases, and ensure the safe operation of the equipment

3.Perfect gas seal saves fuel

High-temperature flue gas flows through the channel between the fixed furnace shell and the rotating furnace liner, and achieves heat transfer with the material through the furnace liner wall.

Adopting a groove shaped pressure control structure and heat-resistant flexible packing sealing technology, reducing the entry of external cold air into the channel, saving energy, and improving thermal efficiency.

4.The unique design of the condenser prevents water pollution discharge, and the cooling water is recycled to save water consumption.

5.Pyrolysis reactor adopts gear transmission, and the front and rear wheel belts and supporting wheels are forged or cast parts that have undergone heat treatment to increase compressive and wear resistance

6.Variable frequency speed regulation for pyrolysis furnace; The speed of the reducer motor can be adjusted

7.Automatic anti coking technology adopts a combination of scraper cleaning device and thermal conductive spherical beads to prevent coking in the furnace.

8.Fully enclosed feeding and slag discharge system is used to achieve high-temperature feeding and slag discharge. Combined with a carbon black cooling furnace, continuous production of equipment is achieved, with fast production speed and high efficiency.

1.Pyrolysis Oil

Directly Used For Industrial Or Boiler Heating (Such As Cement Plants, Steel Plants, Glass Plants, Etc.) As A Substitute For Fuel Oil.

Refined Again Into Non-Standard Diesel That Can Be Used For Trucks, Tractors, Etc.

(Note: The Oil Directly Produced By The Pyrolysis Plant Is Heavy Fuel Oil, Which Can Be Used As Industrial Fuel. If You Need To Obtain Non-Standard Diesel, You Need To Purchase An Additional Set Of Waste Oil Distillation Equipment.)

2.Carbon Black

Sell Out Directly As Coal (Heating Value Is Higher Than Coal,But Cost Is Lower Than Coal,So It Is Easy To Sell Out),Mainly Use To Burn.

Can Deep Processing Into High Grade For Wider Usage,But Need To Invest Grinding Machine.

3.Steel Wire

Sell Out Directly

4.Combustible Gas

Combustible Gases Are Transported To The Heating System As Fuel Supply. Saves Fuel Consumption.

Capacity:15-30 tons per day

Application:waste rubber block (1-2cm), rubber powder, waste plastic, etc

Advantages:Low fuel consumption, low noise, high automation, no secondary pollution

End product:Fuel oil,carbon black

Capacity:15-30 tons per day

Application:Circuit Board

End product:Pyrolysis Oil